Inspect Tunnels, Vaults & Shafts. Detect Risks Early. Keep Operations Running.

From confined spaces to complete insight, DDS3 gives infrastructure operators full visibility and control over dry, hard-to-reach assets.

KEY BENEFITS

End-to-end digitalization:

In one pass (visual, thermal, 3D LiDAR) to build a traceable digital twin of your tunnels and cable galleries.

Zero Risk Inspections:

Non-invasive & safe inspections with no tunnel shutdown or personnel entry.

Early fault detection:

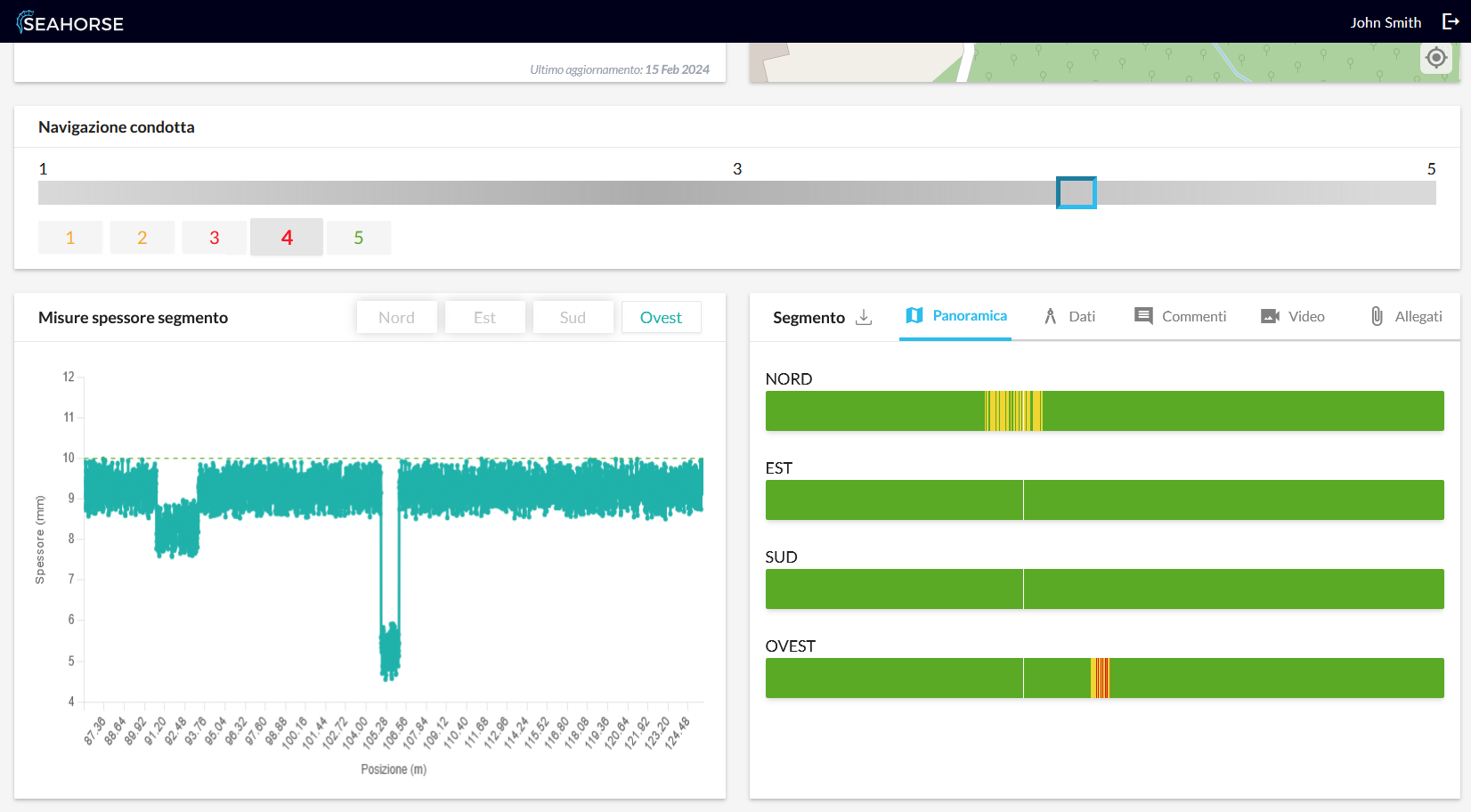

Spot concrete cracks, deformations, and cable hotspots before they cause failures.

Accurate mapping & traceability:

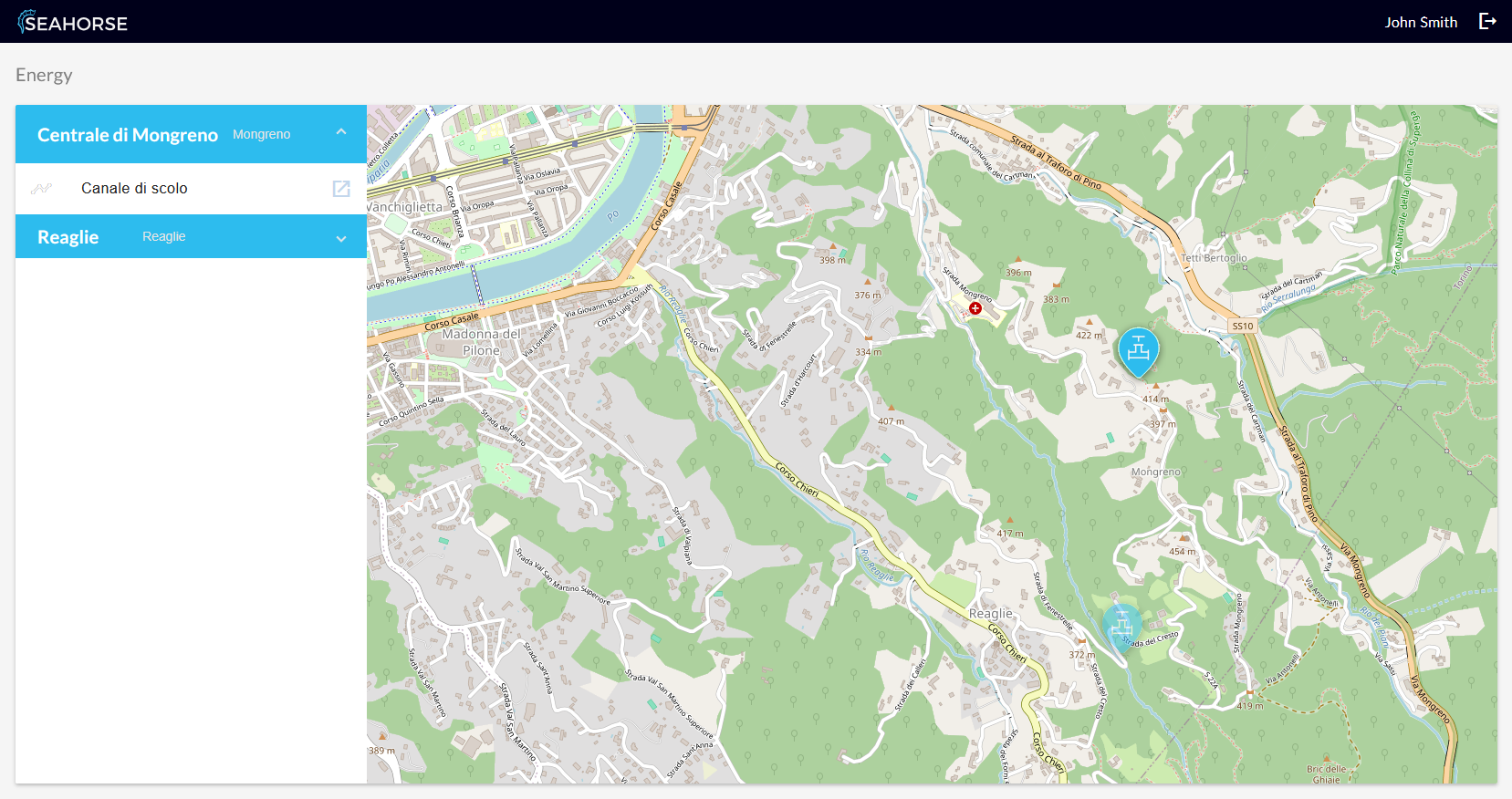

Centimeter-level 3D geometry plus geo-referenced reporting for targeted repairs.

Risk Reduction:

Faster, data-rich inspections that cut O&M costs and reduce unplanned downtime.

ROBOTIC SUITE

Designed for confined, energized environments—utility tunnels, cable galleries and culverts—DDS3’s modular robotic suite enters through small manholes (≥50×35 cm) and navigates long, complex corridors with ease.

It combines adjustable 360° cameras, thermal imaging to reveal hotspots and insulation anomalies, and 3D LiDAR for high-accuracy geometry—delivering a traceable digital twin in a single pass. Operators get real-time feedback and live control via a fiber-optic umbilical, enabling targeted, non-invasive inspections without shutdowns.

Where needed, optional UT modules quantify material thickness on metallic liners or steel elements to support precise repairs.