Revolutionizing penstock and tunnel inspection

From risk to insight: DDS3 transforms inaccessible hydropower assets into fully monitored, maintainable systems.

KEY BENEFITS

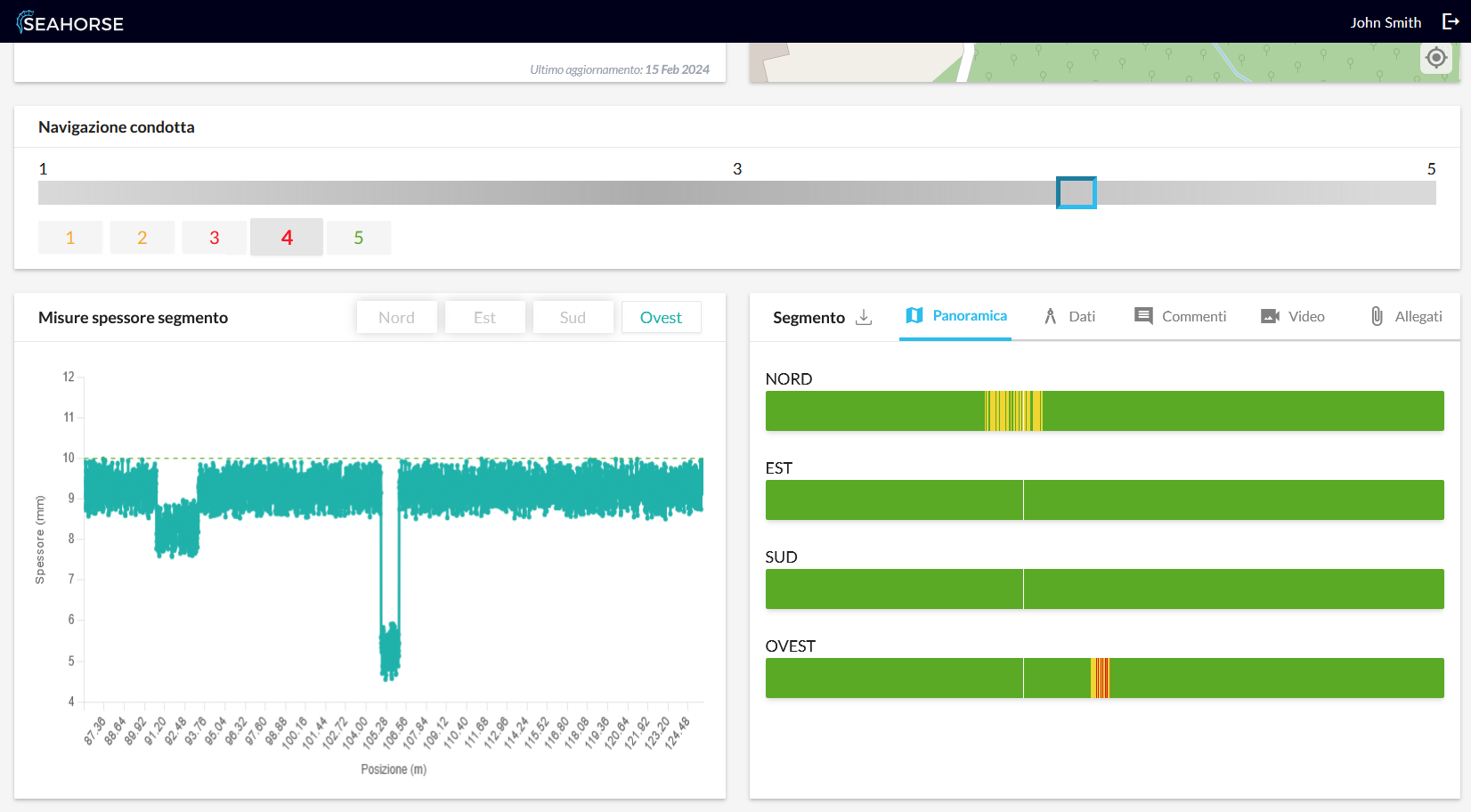

Early Defect Detection:

UT sensors identify corrosion before it becomes critical.

Geometric Analysis:

3D LiDAR and sonar mapping detect deformations, ovalization, and structural shifts.

Proactive Maintenance:

Detailed reports support smart, data-driven planning.

Improved Safety:

No confined space entry or dewatering required.

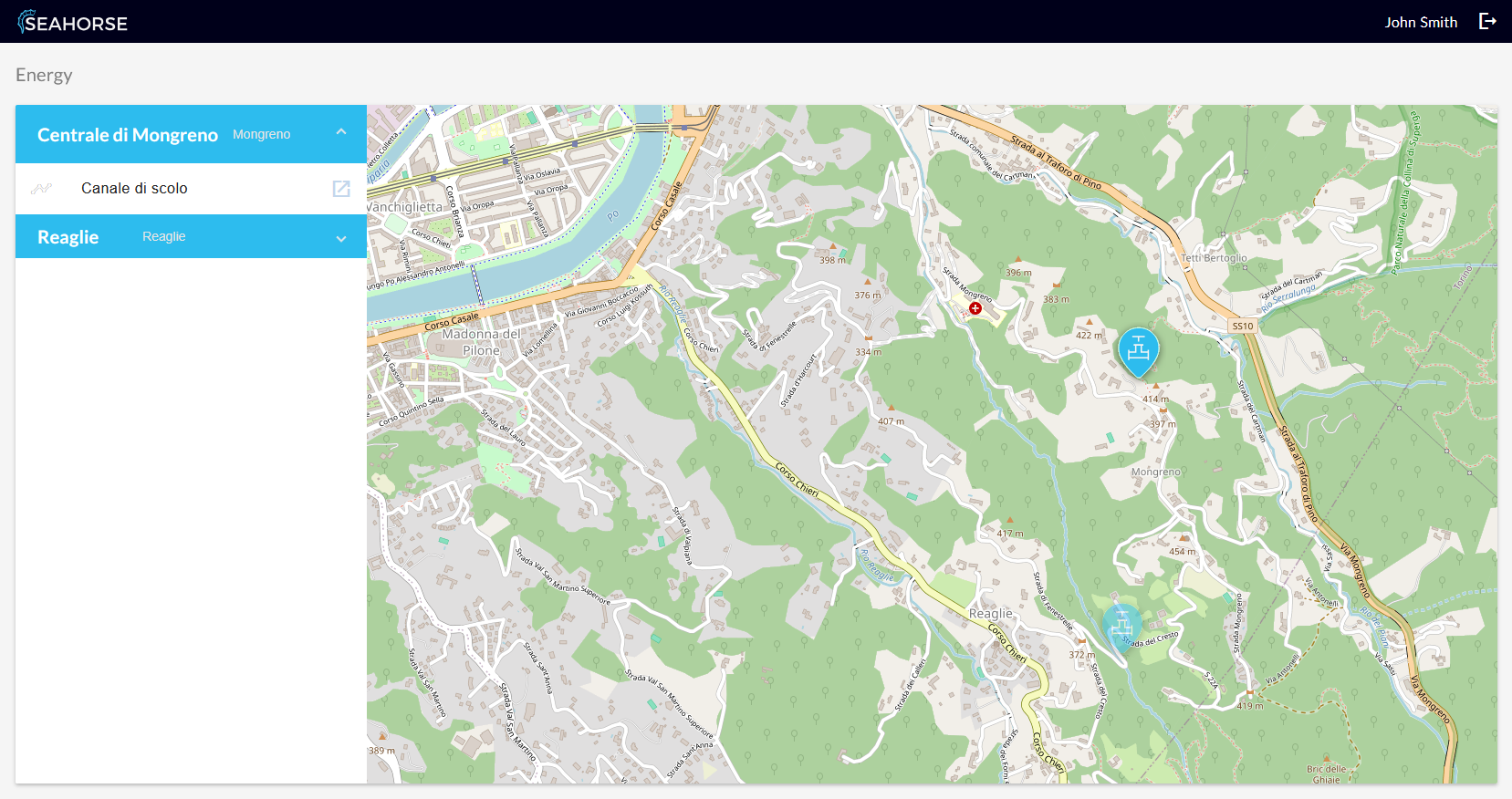

Spatial Referencing:

IMU and encoder data enable full-length positioning with geometry and profile reconstruction.

ROBOTIC SUITE

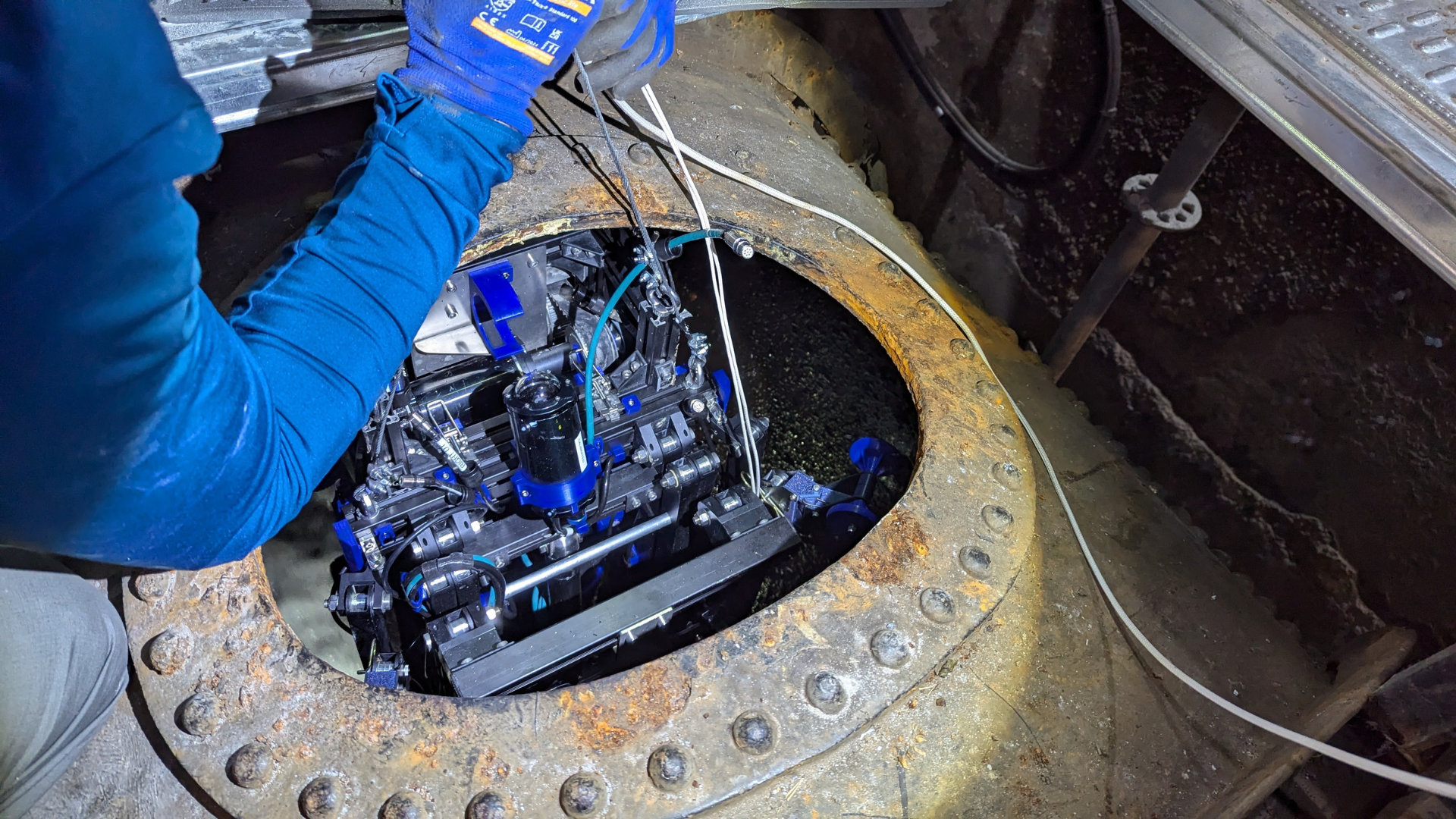

Hydropower plants often rely on decades-old infrastructure exposed to extreme environmental and operational conditions. Penstocks, shafts, and tunnels face corrosion, deformation, and reduced integrity over time — but inspecting them is dangerous, expensive, and often incomplete using traditional methods.

With DDS3, PIPEIN provides a safe and data-rich alternative. Our robotic suite can navigate submerged, pressurized (up to 60 bar), and steep environments with ease, gathering high-resolution data through ultrasonic probes, 3D mapping, and onboard navigation systems. The result is a comprehensive understanding of asset conditions, enabling smarter maintenance strategies and longer asset lifespans.