Prevent Corrosion. Map Assets. Ensure Safety.

From hidden depths to full insight, DDS3 gives offshore operators unparalleled visibility and control over submerged assets.

KEY BENEFITS

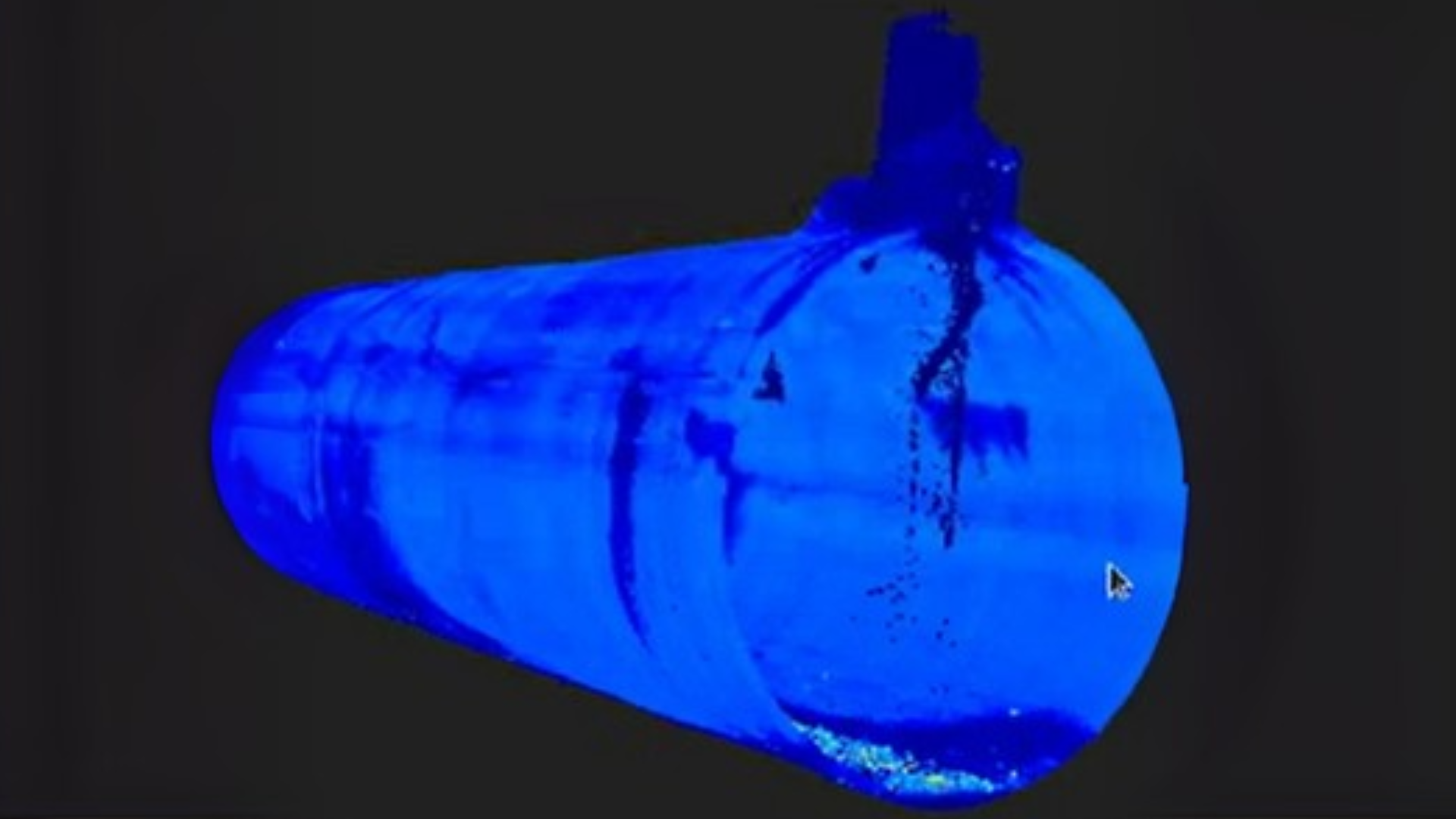

Corrosion Detection:

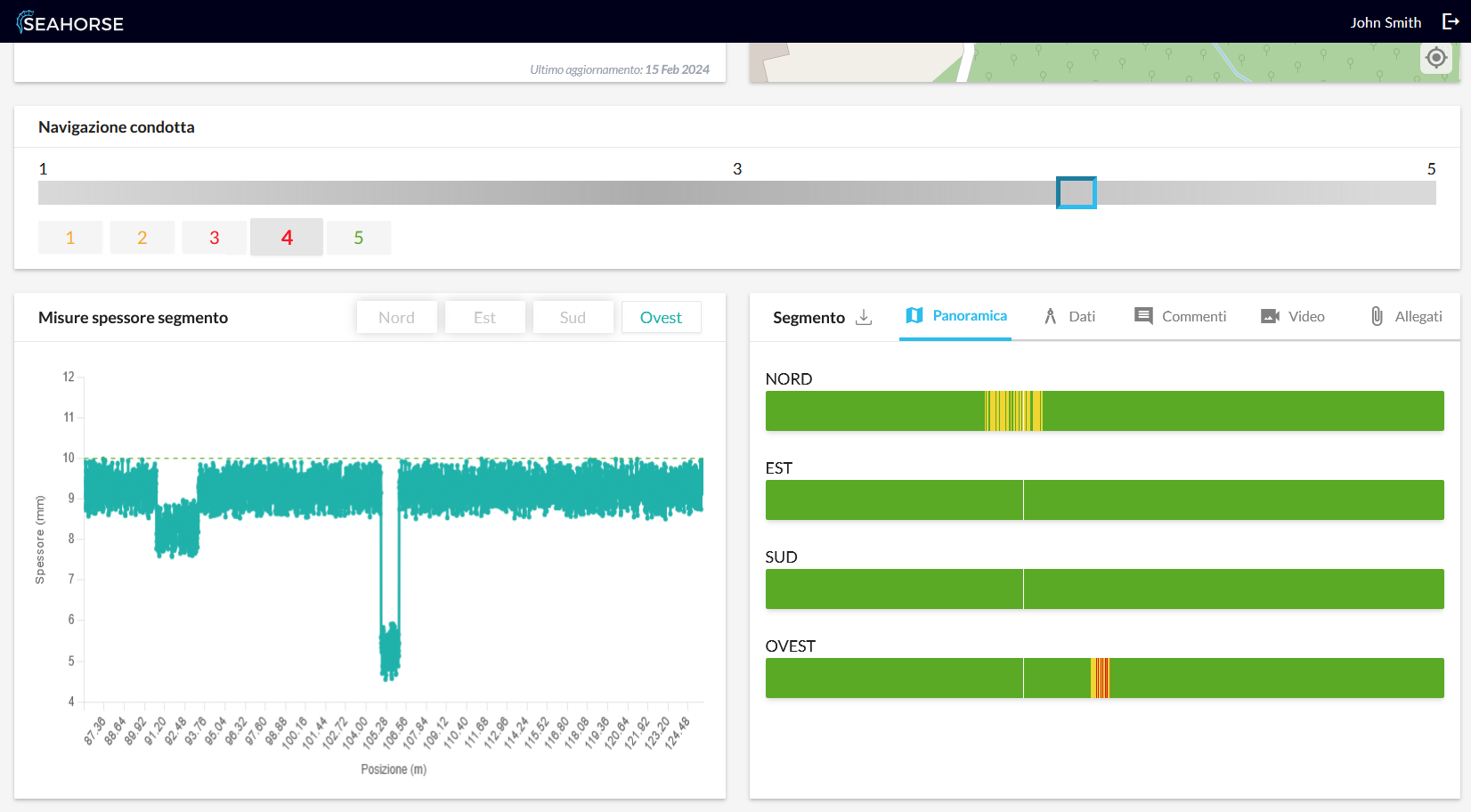

Ultrasonic probes, sonar and cameras identify corrosion, cracks and thickness loss.

Zero Downtime:

Live, through-access-point surveys mean no platform shutdowns and uninterrupted production.

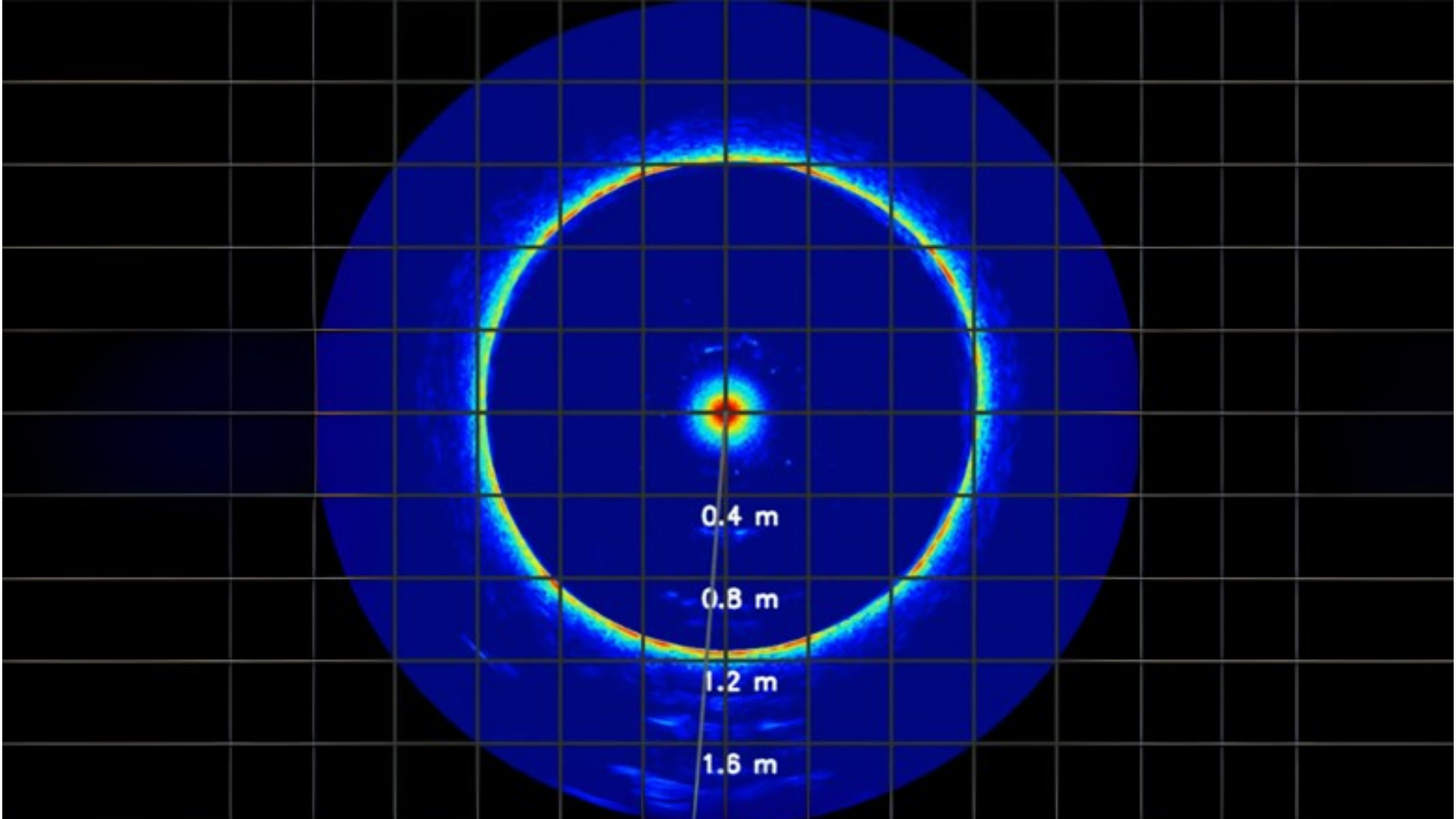

3D Profiling:

Profiling sonar and LiDAR generate high-resolution cross-sections to map deformations, sediment buildup and structural anomalies.

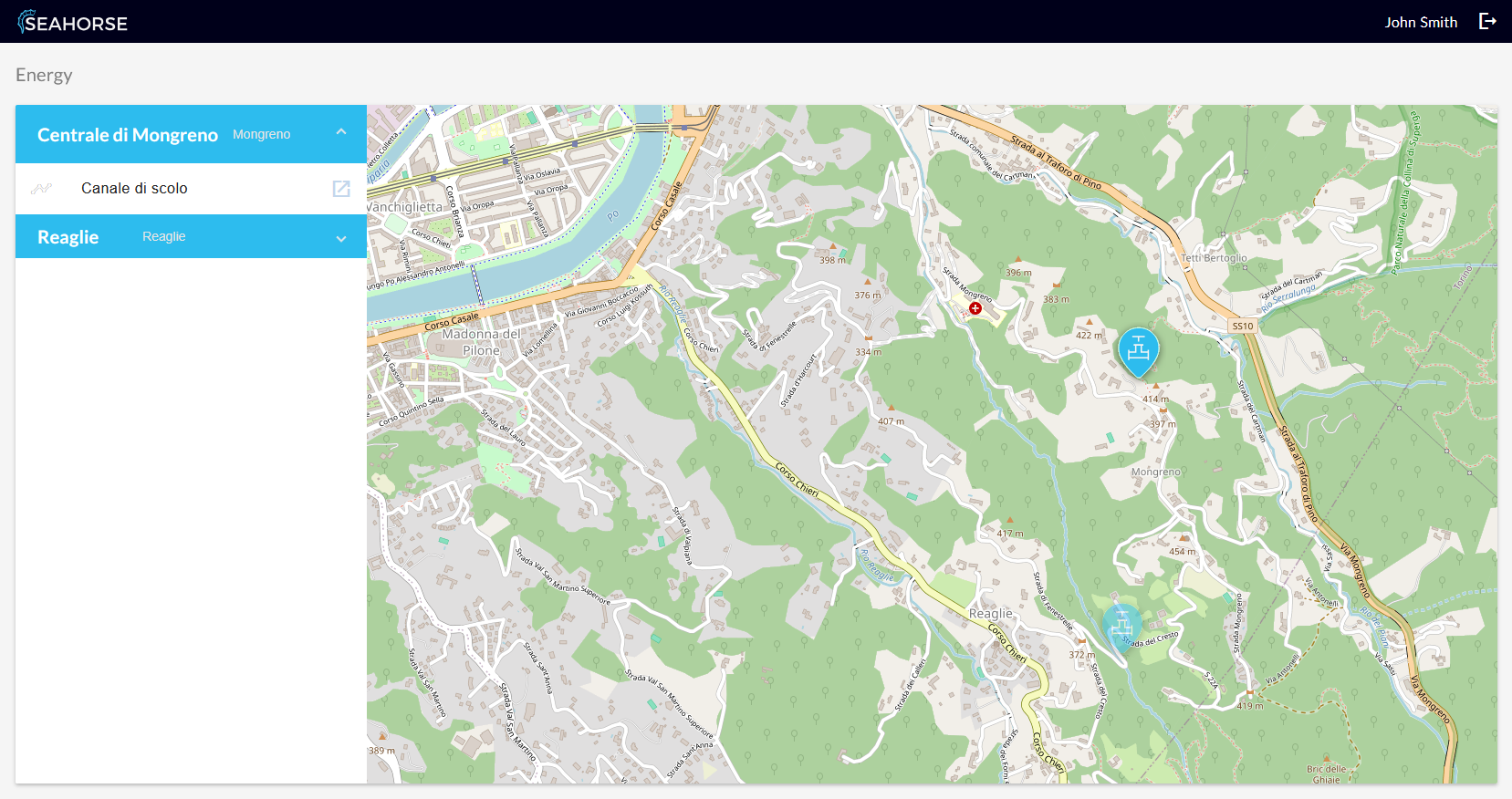

Asset Mapping:

IMU, encoders and sonar fuse to pinpoint defects at exact depths and geo-referenced locations.

Risk Reduction:

Proactive monitoring and fully traceable reports help you meet stringent safety and environmental regulations.

ROBOTIC SUITE

Offshore platforms, risers, caissons, and subsea pipelines operate in high-pressure, saltwater-soaked environments that are often impossible to access by divers or ROVs.

With PIPEIN’s DDS3 you get a non-invasive, data-rich inspection solution that fits through small access points (≥50×35 cm), withstands up to 60 bar, and integrates your choice of sensors—ultrasonic probes, 360° cameras, hydrophones, profiling sonar and 3D LiDAR—to capture corrosion, leaks, cracks, deformations and more in a single pass.